Laser Cutting Design

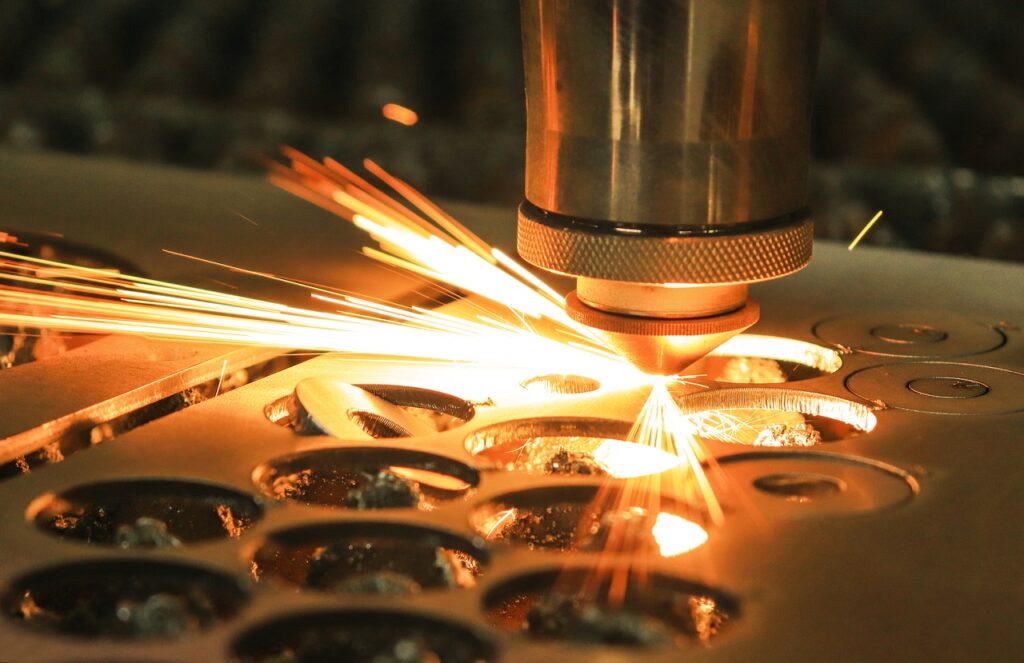

Laser cutting design is one of the services that Contract Manufacturing Specialists of Illinois provide to customers. It is an interesting process that combines technical flair with technical skills. It is an exercise that should be exclusively left in the hands of professionals. It entails the use of high precision laser cutting machines. The experts cut right through the metal surfaces of any size. Modern laser cutting machines can work on thickness of up to 25mm. The good thing is that these machines deliver a very high amount of precision. The guiding principle is to choose a laser cutting design company that has the right expertise and machinery.

The primary advantage of laser cutting design is that it allows for a high degree of precision regardless of the product that you are working on. Therefore, it gives users the opportunity of making intricate designs that the other steel cutting techniques may not provide. A small mistake on the laser cutting design is that it will have adverse effects on your product. In fact, you may end up with a product that is completely unusable. The guiding principle is outsourcing contract manufacturers who have all that it takes to deliver exemplary laser cutting designs.

The imagination of the designer is the only limitation to what you can create using the laser cutting design technique. Once you have an idea of what you want to create, the designer will help you to improve on it for the better. The designer begins by drawing how the complete product will look like after the cutting process is over. In most cases, you will have to use a CAD program or any other similar tool

After this, you have to pass it over to the laser cutting machine. It utilizes the illustration to guide the place where the cuts are made with an accuracy of 0.22mm on a large cutting table. If the expert creates the initial specification in the correct manner, the finished product will perfectly match the original laser cutting design. You can get the best services from Contract Manufacturing Specialists of Illinois. The company has been offering these services to the residents with a very high level of precision.

Therefore, it is crucial for the initial laser cutting design to be correct before you allow the laser cutting machine experts to embark on the project. In the next section of this article, we are going to look at some of the guiding principles when working on the laser cutting design. You will discover that it is a task that you should leave in the right professional hands.

Laser Cutting Design Machines are Literal

The laser cutting machine interprets every line that it sees on a design as an instruction to cut at that particular point. The implication is that you should not add any lines that you don’t want to have the laser cutting steel pass through. You may end up messing your own project unknowingly which is not a good gesture for laser cutting design. This is more important when dealing with decorative lies that could look right on a jewelry piece but you should not cut through them. Experts pay close attention to this laser cutting design element so that they don’t mess up your project.

Remember Physics Laws

One thing you need to remember is that you are cutting several pieces of metal from a single sheet. The meaning of this is that you do not have separate objects. For instance, when you have one object inside a complete gap, you could have the object falling away. You have to make sure that there is a connecting metal piece that will run through the whole design. It is something that laser cutting design professionals pay close attention to when working on your project.

Looks at the Details Closely

It is good to understand that laser cutting machines are so precise is whatever they do. Therefore, it is crucial to examine the line intersections to ensure that they are actually meeting up with the expectation. If this is not the case, you will not be able to cut off the various pieces as expected. The CAD programs allow users to zoom through the tiniest details and grant them an opportunity to ensure that these lines intersect properly before it is so late. At the same point, this provides an opportunity of finding any tiny dots or lines in the image that could be interceptive to the naked eyes but will become intercepted as unwanted cutting instruction. All these things can be avoided with the right implementation of your laser cutting design.

Show Restraint Wherever Possible

When you cut out too many pieces, it can make the whole design fragile and it may even fall apart completely. In case you have so many lines that are intersecting at the same point, this is an excellent opportunity for revising your design so that you can make it stronger in the process.

The Design Should Meet the Specification of the Cutter

The last thing is to make sure that the laser cutting design meets the specification of the cutter. You need to check with your laser cutting service beforehand to ensure that the complete file matches all the technical requirements. Converting the files between various formats may lead to the loss of the required details or imperfections. It is prudent to send a sample file beforehand for checking.

The team at Contract Manufacturing Specialists of Illinois has a lot of experience to guide you through the laser cutting design process. You can be sure of getting the best results even when dealing with the most complex laser cutting jobs. You will discover that the steel laser cutting process is not as complex as you think.

In the modern economic climate, individuals are looking for the best laser cutting designers. With the right professionals, you will get high-quality goods at the cheapest price possible. This is especially true in the market of laser cutting where costs have a crucial role to play in the selection of suppliers. However, costing is only one factor as there are other factors that you need to consider. These include;

Location

You cannot overlook the location of your preferred laser cutting design professional. You need someone who will deliver the goods on time when using their own transport. Also, check whether the professional is close to an airport if you need an international supplier.

Quality Department

You could come across the cheapest laser cutting professionals but make sure that they have the correct quality policy before you place your order. Let the supplier give you some samples of the product or he can give you a trial to help you ascertain his quality.

Storage

If you are ordering bulky products from the laser cutters, you have to make sure that they have enough space for storing your goods. For instance, if you need 1000 parts per week, check whether they can handle the quantity. If not, you can increase the transportation capacity to alleviate the storage problem.

Secondary Operations

Check whether the laser cutting expert provides ancillary services like machining. It is good to go for a supplier who can carry out ancillary operations in-house. If he has any sub-contract suppliers, check whether he has decent relationships with them.

Financial Stability

So many companies credit check their clients but rarely will you find customers credit checking their suppliers. It is good to check the credit stability of the supplier as this will give you the reassurance that he will support you in the long run and won’t leave you without the key materials.

In summary, you can switch laser cutting design suppliers almost painlessly as long as you follow the guidelines that we have mentioned above. Contract Manufacturing Specialists of Illinois remains to be a great option for those who reside in the region of Illinois.

The resources that have allowed us to offer the best quality services at affordable rates. If you need any of them, feel free to request a free quotation from our team now. We have a highly skilled team of professionals who are more than willing to make your dreams come true. You can be sure of getting the real value for your money and reporting a high level of customer satisfaction when you choose to contact our company.

Our core offerings and services at Contract Manufacturing Specialists of Illinois includes, but is not limited to, the following:

We service multiple cities throughout the state of Illinois. We provide all the services listed above, and much more in every city throughout Illinois.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.