Metal Fabrication

If you are always so keen on industrial proceedings then you must have heard about the term metal fabrication. Even though this term might seem so common, their people still do not what metal fabrication is. Those who see or think they know this process only know it as the process of welding.

However, if you look at this process this way then you are very wrong. The fact that the process of welding is a part of the metal fabrication process does not make it entirely a metal fabrication process. The only thing we can say about the process of metal welding in relation to the process of metal fabrication is that it is just part of this process.

Other than welding, we have other processes as well like folding among others that make up the process of Metal Fabrication. If you do not know what the process of Metal Fabrication is then you are in the right place. This is the process that we are going to look at today and see what we can learn about the same.

The perfect place to start with such a conversation is by definition. We need to know exactly what this process is and maybe look at how the whole process is carried out or works.

Metal Fabrication

The process of metal fabrication can be simply defined as that process through which metals are manufactured into various shapes or in some cases end products. This process involves the use of some machines which play different roles during the process.

What most people see later is always the end product of this process. To end up with such a product there are so many things that happen like cutting and folding all of which have to be carried out perfectly. There are so many things that contribute to the success of this process and one of them is the machine used for this process.

If the machines used for this process are not of the right quality then there is a good chance that the results will not be desirable. If the machine used for this process is of the right quality then definitely the results out of this process will be desirable.

If you have ever had an opportunity to look at any metal fabrication product like sheet metal or any other then that is because the piece of metal you see was worked on in the right way. Such pieces of metals do not mean that there are no other metals that are not worked on wrongly, of course, they are.

The only thing that happens is that such metals never make it to the market that’s why you never see them. To carry out the process of Metal Fabrication in the best way possible you need to have the best machines which are largely used to make this whole process a success.

To get these machines you need to visit Contract Manufacturing Specialists of Illinois. This is one place where you can get the very best of machines that you can use for the process of metal fabrication. This process is carried out in various stages and can take a long period of time depending on the product that is being created.

As we have said the process of metal fabrication is very detailed and complex at the same time. Other than that, this is one process that also requires the highest level of accuracy to get the best and required results. To attain this accuracy there are so many things that have to go right and one of them is finding the right people for this process. This for so many years has been a challenge to many people who own Metal Fabrication businesses. If you own a metal fabrication business it is very important for you to look for the right people who will help you to carry out this process in one way or the other.

You need to look for capable people who have experience in all aspects of this area. From operating machines to other areas, you need someone who is well capable and one that will surely help you to work on your specified customer orders perfectly.

The process of Metal Fabrication as we have said is a very complex process but it can be narrowed down to three main stages. These stages are cutting bending and finally assembling. These three are the main processes that make up the metal fabrication process.

We are going to look at these stages briefly and see what happens at each stage and in which way. The first process that we are going to look at is the process of metal cutting.

Metal Cutting

This is the first-ever process in any metal fabrication process. During this process, the raw metal is cut into various shapes and products. The reason why this process is carried out is that it is not possible to work on any metal in its raw form.

For this reason, the metal has to be cut into various pieces that can be used later on for other processes. The cutting process is carried out using various machines depending on the size of the metal as well as the thickness. The metal can also be cut into various shapes depending on the intended final product out of this process.

If there are some serious shapes that have to be arrived at after this process then CNC machines might be used. These machines are known to deliver the best and the highest level of accuracy whenever they are deployed. Other than these machines, we also have other types of machines that are used for this process as well.

Metal Bending

This is the second process that follows up after the process of cutting the metal. Once the metal has been cut into the desired pieces the next thing that has to follow is the bending of these metals. This is also another crucial process that has to be carried out in a very careful way to achieve the desired results.

Bending just like cutting can be done in so many ways depending on the unique characteristics of the metals. The process of bending the metal just like any other process has to be carried out in a very careful way. If you enquired then you will learn that most of the mistakes that occur during the metal fabrication process occur at this stage.

There are so many things that occur during the metal bending process that has to be carried out in the right way. For instance, there is the aspect of angles that have to perfectly calculated and bent. If we have any mistakes occurring then the mistakes will prompt a repeat process which again has to be carried out.

To avoid such a thing from happening it is essential to carry out this process in a very careful. Depending on the desired bent the people carrying out this process have to calculate everything well to achieve the best and desired results.

Some people who value excellent results out of this process use the CNC machines which are very accurate at bending metals.

Assembling

This is the last stage of the Metal Fabrication process anywhere. At this stage, all the work has been done and completed and what is remaining is only the assembling process and that is exactly what happens here. All the metal that has been worked on is normally put together to create the final product.

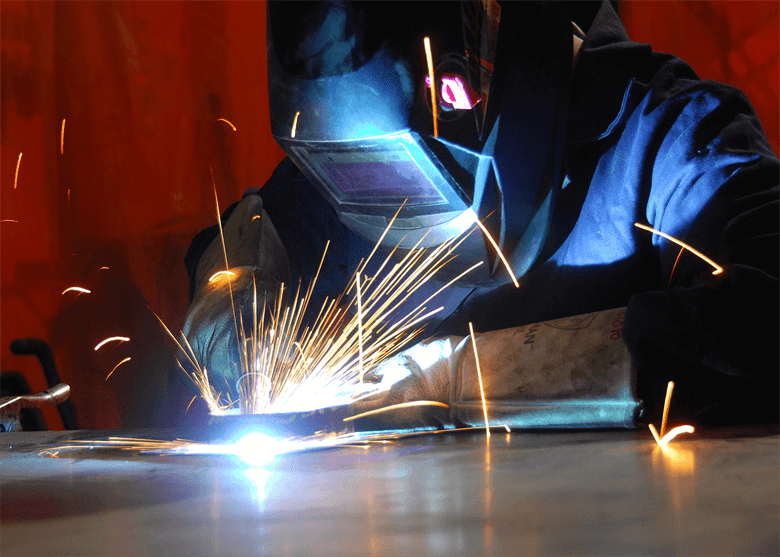

The process of assembling is done through so many steps among them welding together with many more others. If the process is not done through welding then we could have other procedures like joining parts together using screws among other procedures.

In summary, this is what the process of Metal Fabrication is all about. It is a very complicated process that touches on so many parts and has to be carried out well by the right people. The best brand to help you with such kind of work is the Contract Manufacturing Specialists of Illinois.

The resources that have allowed us to offer the best quality services at affordable rates. If you need any of them, feel free to request a free quotation from our team now. We have a highly skilled team of professionals who are more than willing to make your dreams come true. You can be sure of getting the real value for your money and reporting a high level of customer satisfaction when you choose to contact our company.

Our core offerings and services at Contract Manufacturing Specialists of Illinois includes, but is not limited to, the following:

We service multiple cities throughout the state of Illinois. We provide all the services listed above, and much more in every city throughout Illinois.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.